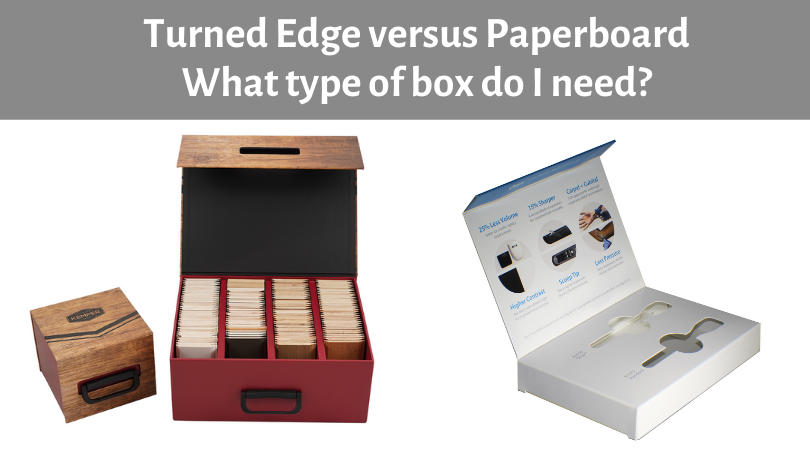

There are 3 major differences between Turned Edge Boxes and Paperboard Boxes.

For the purposes of this article, let’s refer to subject boxes as turned edge. They’re also referred to as cased, set-up and rigid boxes.

If you were to hold a turned-edge box in one hand and a paperboard box in the other hand they might look similar, but there would be some key differences. Here’s how to identify the difference: The easiest way is to look at the corners. Paperboard boxes use lighter weight stock that’s folded over to form a box. A turned edge box will have solid corners. A turned edge box is also usually much more rigid (hence the alternate name) than paperboard.

A turned edge box differs from a folding box (paperboard) in three major ways:

1. Once manufactured, a turned edge box will not collapse like a folding carton.

2. The chipboard used for the walls of a turned edge box is as much a four times thicker than the paperboard using for a folding carton. The gauge of the board used is determined by the application, and customer’s priorities.

3. Printing/decoration is applied to a separate “wrap” which is then applied to the box. Unlike paperboard which is printed on directly. There are many materials suitable for turned edge box wraps, from printed litho stock, to coated papers and fabrics with various finishes and textures. Lamination is often applied for further protection.

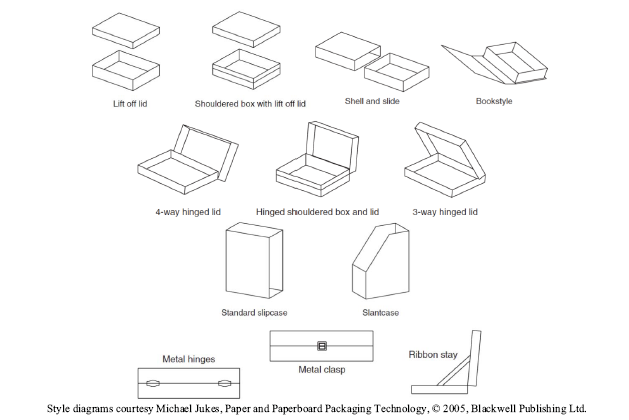

There are many different box style from two piece boxes with lift off lids, to cigar style boxes, to 3-way hinged boxes. Check out this diagram that shows the different types of turned-edge boxes we can manufacture:

In addition to the styles shown above, we can add other custom features to your turned-edge boxes such as:

- Closures – friction, velcro, snap-lock, magnetic

- Handles – plastic, metal, leather, hinged, riveted

- Internal Compartments – columns, layers, custom cut / formed trays

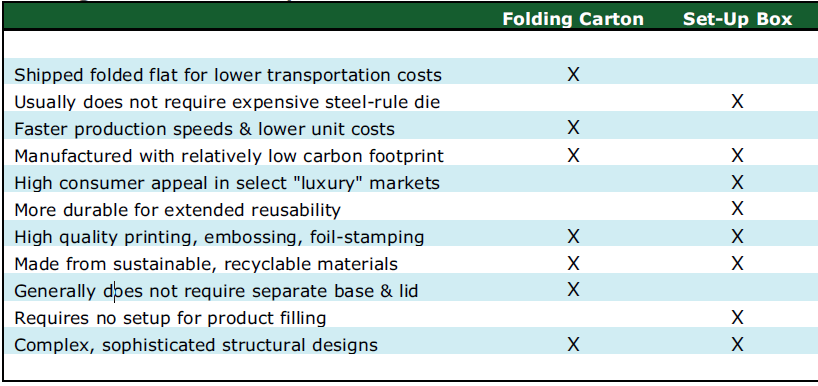

Here are some of the key manufacturing differences between Turned-Edge Boxes and Paperboard (folding) Boxes:

Contact us today for your box manufacturing needs.