How can I customize a ring binder?

Here are 6 questions to answer when customizing a ring binder.

Every binder we produce at Forbes is a custom ring binder. The beauty of that is that we can meet just about every need our clients have for document storage in ring binders. What they need all depends on how they are using the ring binders from the size and shape of the binder rings, to how many rings, to how the binder is decorated, to any closures, to the size of the binder, to materials used, and on and on and on… But customizing a ring binder does not have to be complicated. We’re the binder experts, so let us break it down into the 7 categories of binder customization and the questions you’ll be asked by your binder manufacturer (or the questions they should be asking you).

What is the sheet size you’ll be putting in your ring binder?

Size matters when it comes to selecting your binder size? We can customize the size and layout of the ring binder based on the sheet size you’ll be storing in the binder!

- Will it be standard letter size?

- Will your binder store legal size paper in a landscape format?

- Is it a half sheet size? (Often called junior binders or memo binders)

- Are you storing oversized sheets or boards? (Swatch and sample binders are often oversized, so larger custom sheet sizes may be used in this instance.)

Knowing the sheet size is the first step to determining the actual size of your ring binder. We think it’s pretty cool that we can manufacture a ring binder to your specific sheet size needs.

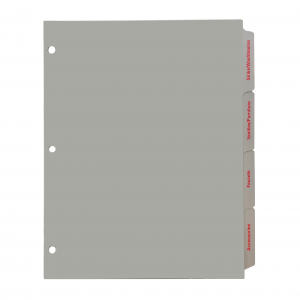

Will you be using index tabs in your ring binder?

This is a question that gets overlooked a lot. But knowing whether or not you’ll use index tabs in your ring binder matters. If we know that a customer needs to use index tabs, we’ll often add about 1/2″ to the width of the front and back panels of the ring binder to accommodate for the tabs. Nothing is more unsightly than a closed binder with the tabs sticking out! Plus that leaves your tabs exposed and more likely to become damaged. Something as simple as adjusting the binder’s overall size can make a huge difference for such a small detail.

Additionally, will you have other oddball sized inserts or content in your ring binder that should be considered when determining the final size of your ring binder?

What ring configuration do you need in your binder?

It’s possible you haven’t even consider what type of ring you need in your binder. There are 3 common ring styles. They are Slant-D, Straight-D and Round or O-Rings. There are other ring formats, but those 3 are the most common. Here is a little more info to help you better understand their uses.

- Round or O-Rings are mounted on the spine of the ring binder This means the covers, front and back might not need any extra width. The continuous curve format makes turning the pages a breeze. O-Rings can accommodate many different page sizes and needs. One drawback with O-rings is that if your binder index tabs have more than one layer, the bottom layer may not be seen at a glance.

- Straight-D Rings are mounted on the back cover of the ring binder. In a D-ring, the paper is held evenly on the right, meaning that your tab dividers all line up and there is a clean line of paper. The paper rests on the flat part of the ring when it is closed. With D-Rings, the binder will need extra width added to accommodate for how the paper sits in the binder itself when open and closed.

- Slant-D Rings are also mounted on the back of the spine and the same width considerations apply as above. Slant-D format is incredibly useful in thicker binders where there are many index tabs. All index tabs should be visible with a Slant-D ring.

With the ring format, you’ll also want to determine the capacity of the ring… In other words, how many sheets of paper will you be storing in your binder, and what is the thickness of the paper? Standard Ring Capacities are as follows (based on 20# bond paper)

- 1″ Ring O-Ring will hold 170 sheets of paper

- 1″ D-Ring will hold 220 sheets of paper

- 1-1/2″ O-Ring will hold 250 sheets of paper

- 1-1/2″ D-Ring will hold 350 sheets of paper

- 2″ O-Ring will hold 350 sheets of paper

- 2″ D-Ring will hold 450 Sheets of paper

- 2-1/2 O-Ring will hold 450 sheets of paper

- 2-1/2″ D-Ring will hold 550 sheets of paper

You can see that knowing how many sheets you’ll be storing in your ring binder helps determine the size and format of the ring you’ll want.

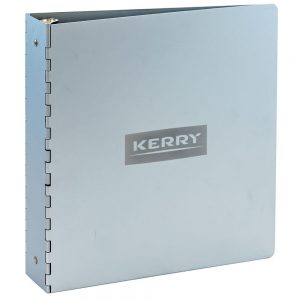

How durable does your ring binder need to be? How will it be used?

Sometimes you have an idea of the materials you want for your binder, but how the binder is being used will matter. For example:

- If it’s a presentation you are making and the binder will not need to withstand heavy use, a turned-edge binder may be a good solution to provide maximum branding impact.

- If the binder will be exposed to extreme temperatures there are specific materials that will and wont work for your binder.

- If your binder will be exposed to liquids or moisture, you’ll probably want a poly or vinyl binder that can be wiped clean. Menus are a perfect example of when you’d want to give careful consideration to the materials you select. A drink spilled can quickly ruin a menu cover that is not designed to withstand being wiped-down.

- Will the binder need to withstand heavy, rugged use, such as on a construction job site? In this case, you might want aluminum which will withstand being dropped, and constantly moved and exposed to varying temperatures and situations.

- On the flip side, you might want aluminum, but it’s really the look you’re after and the construction is less important… We can create a turned-edge binder that is printed to look like aluminum, that could meet your needs.

These are just a few examples, but you’ll want to consider how long the binder needs to last and how the users will handle it and use it. Knowing this information can help you choose just the right materials for the job.

What kind of artwork will be used on the ring binder cover?

This can be a show stopper when you think you want a certain material, but you also want a certain type of branding or decoration. If you are wanting a full-bleed 4-color printed cover, you’ll probably want to consider poly or turned-edge construction. But if you are considering just a stamped one-color logo your options become limitless. Gold foil stamping only works on certain materials. And cloth covers are limited to what you can do as well.

Knowing what you want on your covers, both inside and out, will help determine what materials we can use. We can print binder covers to look and feel like various materials such as wood and aluminum, but at a much lower cost than using those actual materials. The type of artwork you need helps determine the best materials to use.

Will your ring binder need built in pockets?

Will your ring binder need a space for business cards or other pockets? You can customize a ring binder with pockets on the inside front and back cover for things like business cards and full size sheets of paper? Pockets are a great way to add functionality to your binder.

In addition to those 6 questions, your overall budget will be a consideration in how to customize your binder. How many you need for the order can impact the cost based on some of the customizations. When you are upfront about your budgetary needs when designing a custom ring binder, we can come up with a perfect solution that will work for everyone, while still delivering you a premium, custom made ring binder.

Need help designing a custom ring binder?

Contact us today to get started and we will walk you through the process!